|  |

|  |

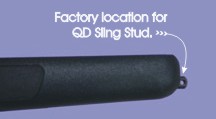

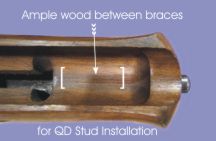

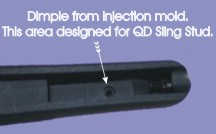

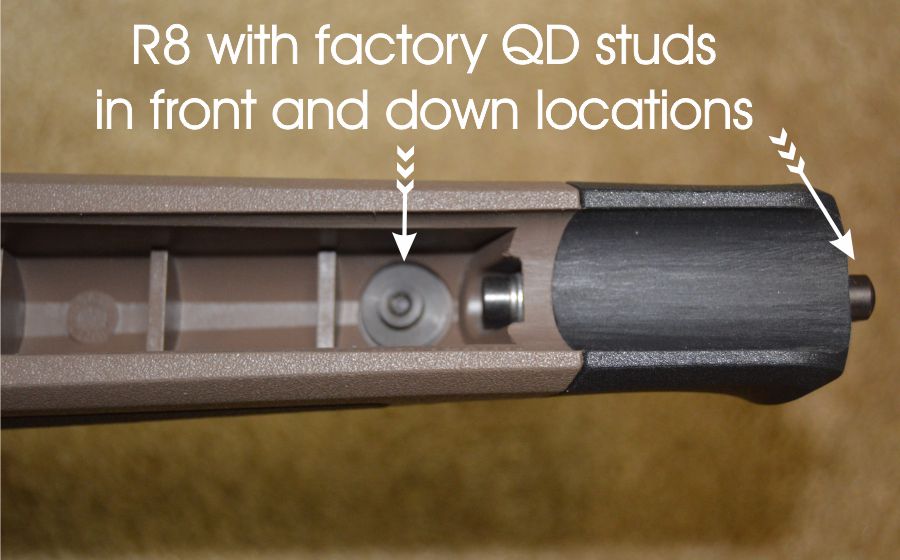

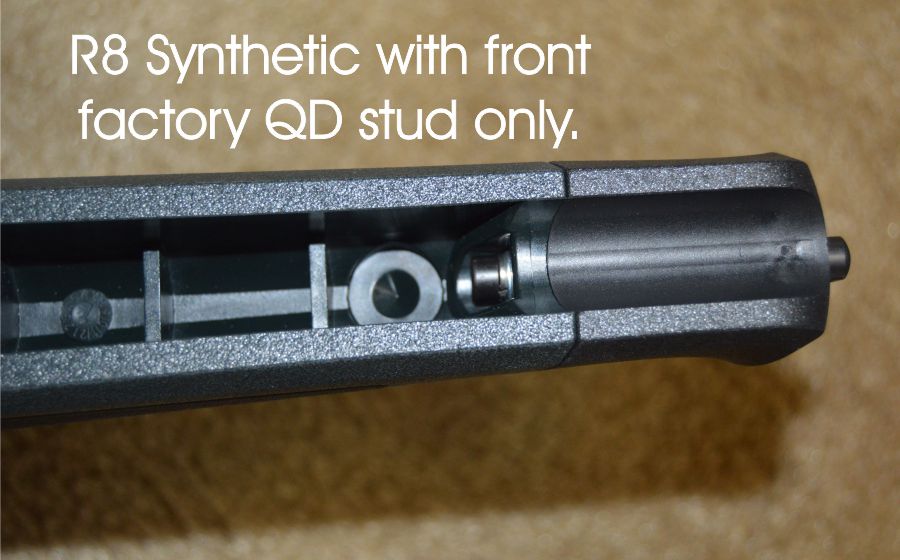

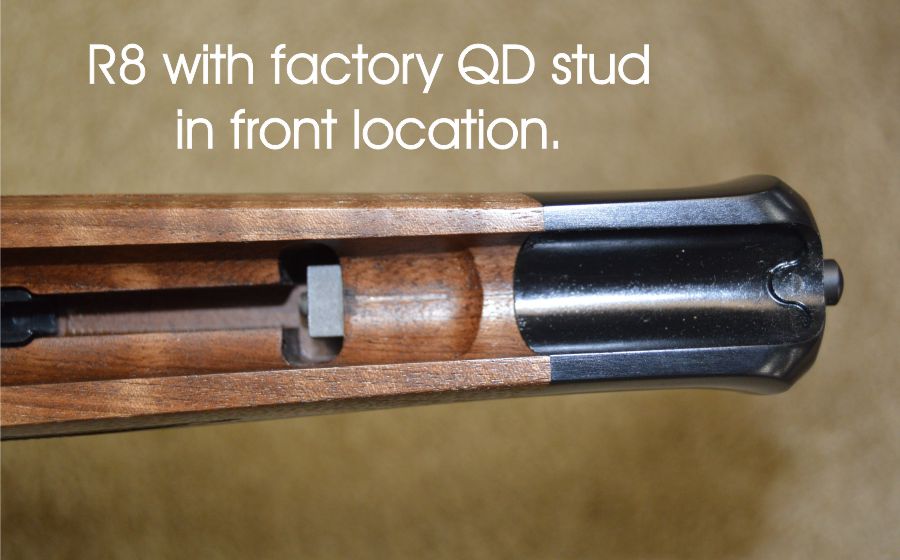

As illustrated in the accompanying tables, the typical location for a QD Stud on a Blaser R8/R93 is straight out the forearm of the rifle. Special note, some of the newer R8s come with dual QD studs, both forward and downward from the Blaser factory! The SnipePod V2 V2-QDMT only functions correctly in on the downward QD stud. Fortunately Blaser provide abundant material to install a QD Stud in the more traditional downward position. The wood model Blaser R8/R93s have a generous amount of wood for installing wood-screw style QD-Stud. With the Synthetic R8/93s, Blaser went even further and designed the injection mold with a liberal amount of material in the forearm, and a dimple identifying the desired location for the QD-Stud.

One key advantage to the SnipePod V2 that deserves special note is the fact that attaching the SnipePod V2 V2-QDMT applies no pressure against the rifles stock. The wood stock Blaser R8/R93 has a very pronounced Schnabel forearm. Even after relocating the QD Stud, most bi pods would not be able to attach because of the Schnabel forearm, this is no problem for the SnipePod.

|  |

with factory installed dual QD studs | dual factory QD studs |

|  |

front QD stud only note dimple location for downward QD stud |

|

| 45° QD Stud |

There are several stock and rifle manufacturers that like to mount the QD Stud at a 45° angle, right at the tip of the forearm. This seems to be more popular amount the ultra light weight mountain rifle manufacturers, with Rifles Inc and MPI Stocks coming to mind.

Although it is possible to mount the V2-QDMT to the QD-Stud in this position, it does have its limitation. The SnipePod V2 is designed with a rotation release mechanism that allows the SnipePod to rotate and lay under the rifle for stalking/transporting and forward for storage under the barrel. This feature is limited with the 45° QD Stud location.

We recommend...

Consider the fact that these types of rifles are so light (many under 6 pounds), they benefit greatly from the

stability of the SnipePod V2.

This is a question that we get frequently. Many Harris bipod owners opt to carry only the smaller prone Harris because of weight issues. Unfortunately in most hunting situations, especially mountain conditions, prone bi pods are impractical. Harris does offers a taller sitting model called the 27SC. Lets compare the 27SC to the V2-27 SnipePod. The Harris 27SC model provides a modest 20° of canting (compare that to 80° of the SnipePod!). The 27SC tips the scales at over 21 ounces. In comparison, the V2-27 SnipePod V2 is barely over 5 ounces. And remember, only the V2-QDMT remains semi-permanently attached to the front of the rifle, and in weighs only 110 grains (that is about equal to a large .243 bullet!).

By upgrading to the SnipePod V2, you will remove 21 ounces (16 ounces = 1 pound), from the front of your rifle.

Surprisingly, this is a popular question. So here goes...

No.

The upper hemisphere of the ball socket is formed from Delrin 150 acetal resin. The ball is held in place by a 6061 aluminum keeper with a Delrin 150 O-ring pressing against the ball. There is no metal-to-metal contact.

Technically Delrin is self lubricating, but oil will not harm it. Lubricating the 416 stainless steel push/pull pin and release pins with a light gun oil is a good practice.

The tension of the ball sockets is set at the factory with a torque wrench.. The tension is enough so that if the firearm is picked up, the legs will remain in whatever position they last were in when resting on the ground. If you bump the legs while they are in the air, they will move. They will not move from their own weight or dangle loosely.

Tension can be a personnel preference issue. The tension can be adjusted with a standard 1/2" open end/box end wrench and a 1/8" hex wrench.

Unless special arrangements are made, we use UPS Ground to ship to the lower 48 states.

We use USPS Priority mail to ship to Alaska and Hawaii.

To ship to Canada we use the USPS and Canadian Postal system. Canadian shipments typically are as fast as USA shipments in about 90% of the cases. The other 10% mysteriously can take as along as 3-4 weeks.

Other overseas orders will also be shipped via USPS.